|

| Water Supply in High Rise Buildings |

Introduction:-

In General

- Designing skyscrapers is an extremely complicated art that integrates several different logistic operations and utilities.

- Plumbing is one of the more challenging problems to solve due to the loss of pressure as water travels up a vertical pipe.

- As the building gets taller, another problem arises as the water pressure at the bottom of a vertical pipe becomes too great for safe operation and building codes.

The Solution

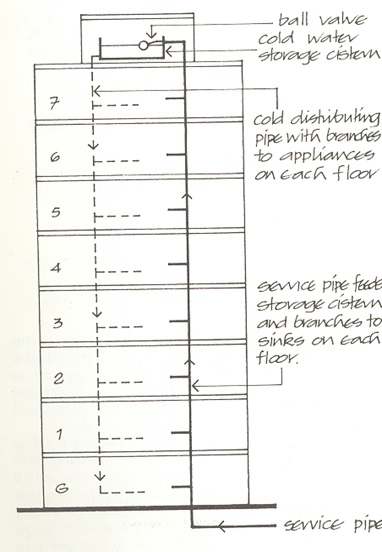

- The early solution to this problem was a water tank mounted on the top of a building with fill pumps at the bottom of the building, a simple gravity down feed arrangement.

- Today, a system of pressure-reducing valves and sub-risers is used to manage the inconsistent water pressure throughout a skyscraper.

- Pressure-reducing valves reduce the pressure at the bottom of the building, while sub-risers increase the pressure for the skyscraper’s upper floors.

DISTRIBUTION SYSTEMS

DISTRIBUTION SYSTEMS IN HIGH-RISE STRUCTURES

– Direct Supply System

– Direct Pumping Systems

– Hydro-pneumatic Systems

– Overhead Tank Distribution (Down Feed Arrangement)

DIRECT SUPPLY SYSTEM

– Useful when pressure is available round the clock at the topmost floor.

– The pressure may not be available so generally floors above 2nd or 3rd storey face shortfall of water pressure.

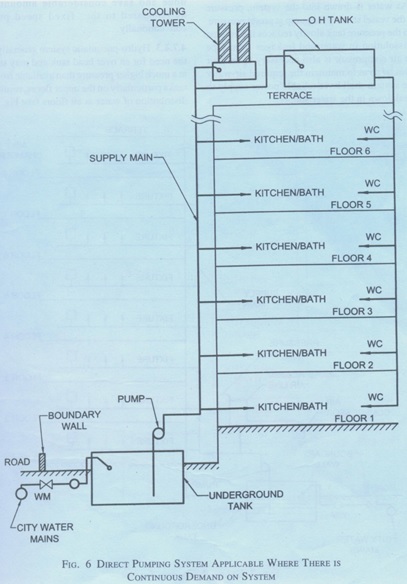

DIRECT PUMPING SYSTEMS

- Water is pumped directly into the distribution system without the aid of any OHT except for flushing purposes.

- Pumps – controlled by pressure switch installed on the line.

- Useful in buildings where a certain amount of constant use of water occurs.

- The system requires a constant and reliable supply of power.

- Power failure – the breakdown of the water supply system.

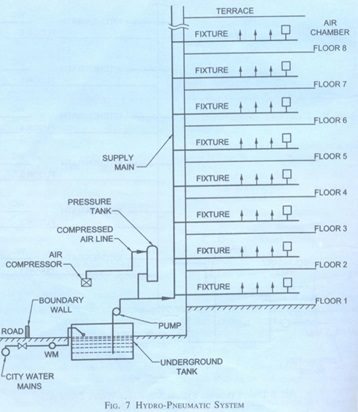

HYDRO-PNEUMATIC SYSTEM

-

Variation of the direct pumping system.

-

An airtight pressure vessel is installed on the line to regulate the operation of the pumps.

|

| Hydro-Pneumatic System |

-

The pressure switch installed in the pressure vessel/tank switches off after reaching the predetermined pressure when the operating pump is put to stop.

-

An Air compressor is necessary to feed the water with air to maintain the air-water ratio.

-

This system eliminates the need for an OHT and supplies water at a much higher pressure resulting in even distribution of water on all floors.

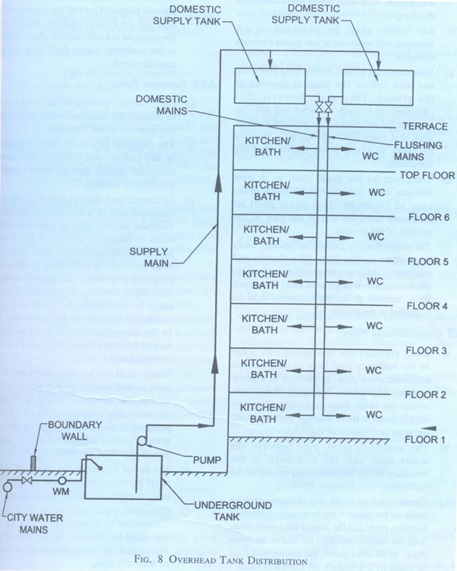

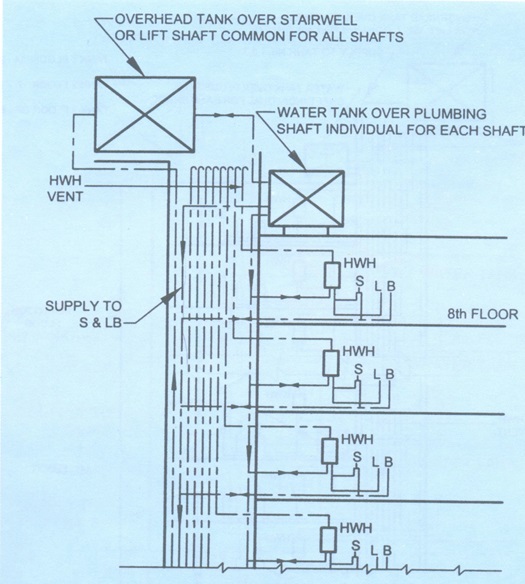

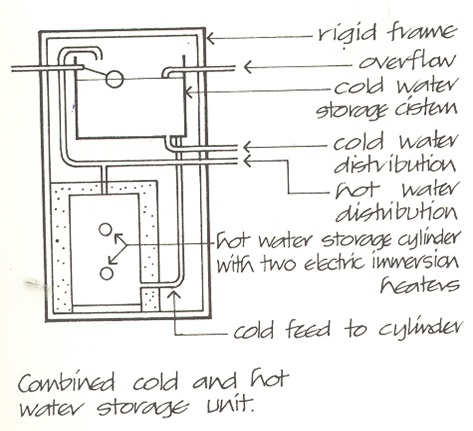

OVERHEAD TANK DISTRIBUTION (Down Feed Arrangement)

|

| Overhead Tank Distribution |

-

The system comprises water to one or more OHT placed at the topmost location of the hydraulic zone.

-

Water distribution- through pipes generally located on the terrace through gravity (down feed)

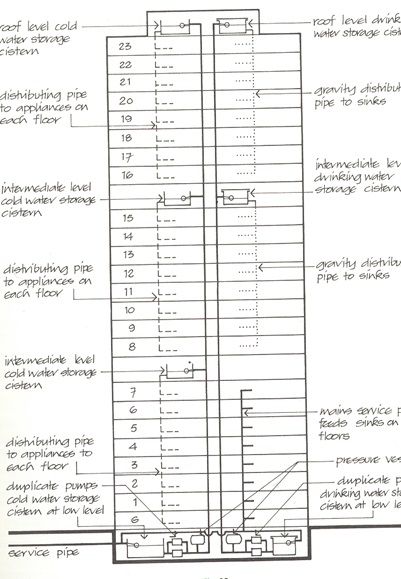

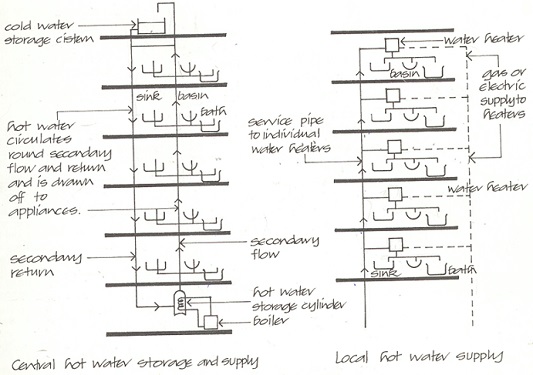

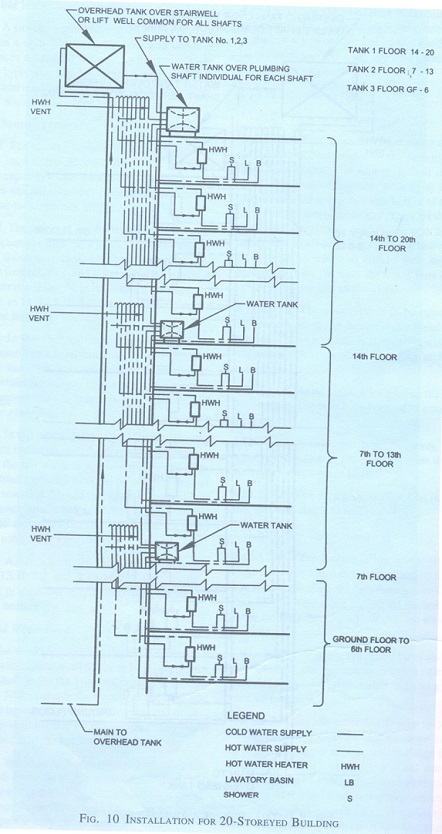

WATER SUPPLY FOR MULTYSTORIED BUILDINGS

|

| WATER SUPPLY FOR MULTYSTORIED BUILDINGS |

-

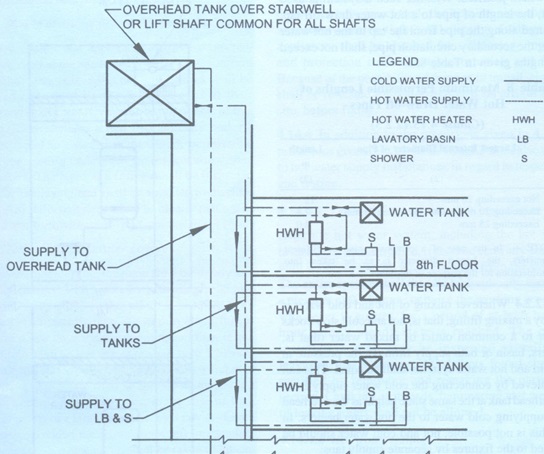

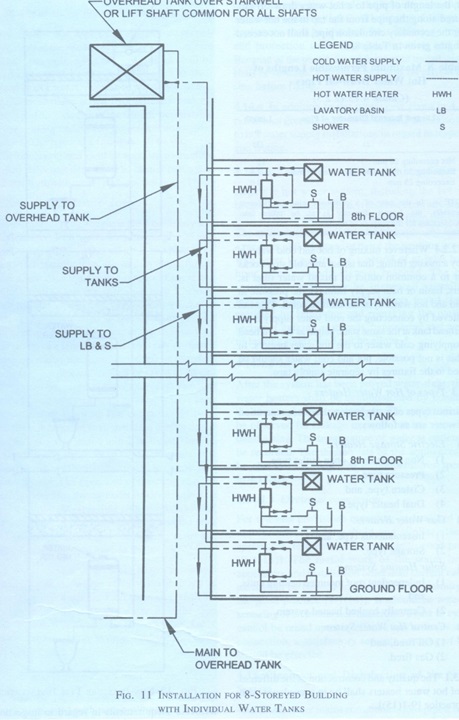

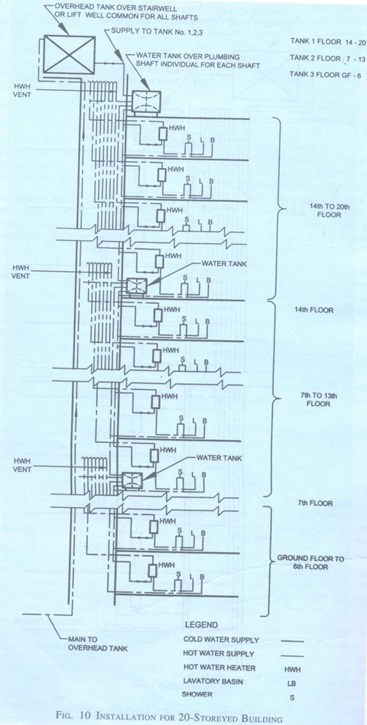

In very tall buildings it is advantageous to use separate drinking and water ground, intermediate, and roof level cisterns. The separate drinking and cold water cisterns spread a load of water storage up the building and limit pressure in the distributing both to drinking outlets and sanitary appliances.

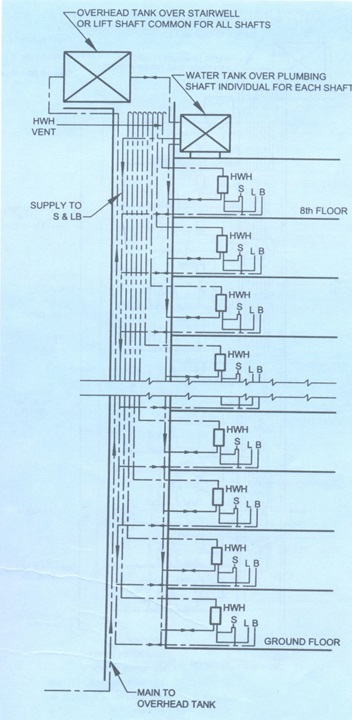

HOT WATER SUPPLY

HOT WATER SUPPLY

-

Dividing the building into different zones

Drainage in High Rise Buildings

Drainage

-

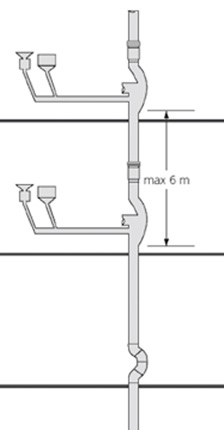

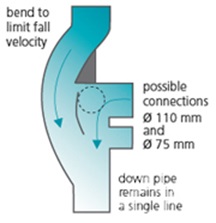

Drainage is another common issue in skyscrapers and is often just as difficult to solve as water pressure problems.

-

When water falls vertically down a pipe, the water will adhere to the pipe’s walls until the pipe’s cross-sectional area is about one-fourth full.

-

Once the gravity propelled water hits a horizontal bend in the pipe, the flow velocity drops dramatically and fills the pipe considerably more due to the lost speed.

-

It is common practice to use relief or yoke vents to slow the water before it encounters a horizontal flow change.

-

The piping at the base of a vertical drainage column must be secured, as to reduce the risk of breaking joints.

Venting

-

Once the water is raised and used, it is discharged to a drainage system that includes a venting system- responsible for the flow of air in the drainage piping network.

-

Air is critical to the drainage process because drainage flow is caused by sloping pipes, and the motive force is gravity.

-

Absent air, the drainage would range from erratic to nonexistent.

-

When the water in a pipe flows to a lower area, air must be added to replace the water, or a negative pressure zone will occur.

-

If this zone is near a fixture, air will be drawn into the drainage system through the fixture trap with an easily identified gulping sound and very slow drain performance.

-

This condition leads to poor performance throughout the drainage system and traps seal loss due to siphoning or blowout.

-

It is however okay to place air vents in the fixtures themselves to increase water flow.

-

As the number of fixtures increases, venting needs do as well, and a venting system evolves, with the branch, circuit, and loop vents at the appropriate locations.

-

Aside from relieving pressure in the drainage system, the vent system allows air to circulate in both directions in response to the fluctuating flow in the drainage system.

-

In many high-rise vent designs, where stacks need to offset horizontally on a given floor, a relief vent is required.

Drainage System

The following are the piping systems adopted in drainage of the high rise structures:

-

Two-Pipe System

-

One-Pipe System

-

Single Stack System

-

Single Stack System (Partially Ventilated)

TWO-PIPE SYSTEM

-

Ideal when the location of toilets and stacks for the WC’s and waste fittings is not uniform or repetitive.

-

In large buildings and houses with open ground and gardens, the sullage water from the waste system can be usefully utilized for gardening and agriculture.

-

In high rises, the sullage is treated within the building for re-use as makeup water for cooling towers for air conditioning system and is used for flushing water-closets.

-

Care should be taken that it has no connection with any water supply line, tank or system used for domestic and drinking supply.

ONE-PIPE SYSTEM

- Suitable where toilet layouts and shafts are repetitive. Requires less space, and is economical.

- The continuous flow of water from waste appliances in the pipe reduces the risk of blockage.

- The system eliminates the need for a gully trap which requires constant cleaning.

- Prevents pipe crossing problems and saves space

- It May not suitable if the flow is heavy.

SINGLE STACK SYSTEM (without vent pipe)

-

Suitable where toilet layouts and shafts are repetitive and there is less space for pipes on the walls.

SINGLE STACK SYSTEM (partially ventilated)

-

Is the same but the only modification is that it is partially ventilated.Also, you can connect the waste appliances such as washbasin, bathtub, sink or sink to a floor trap.

Pingback: ArchiCrew India